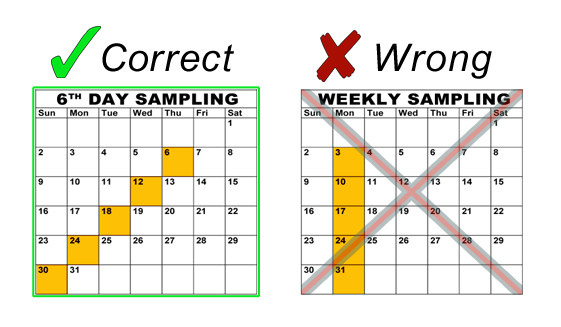

IDEM’s air toxics monitoring program utilizes canisters for the collection of air samples. Special 6-liter stainless steel Suma canisters at IDEM’s air toxics monitoring sites draw ambient air into their chambers for 24 hours on a one-in-six day sampling schedule. A regulator controls the flow of air into the canister and enables it to fill to the desired pressure and obtain a representative sample over the 24-hour sampling period. Air flows into the canister at approximately 6.5 cubic centimeters (cc) per minute. As illustrated below, canisters collect samples every sixth day so that the samples will represent every day of the week and every range of weather conditions. If samples were taken on the same day each week, they would not cover any variation in emissions throughout the week.

IDEM collects the filled canisters for the analysis of air samples in the agency’s in-house laboratory. In the laboratory, staff members log all canister samples, including the sample location, sample date, canister number, and sample pressure in the canister. Chemists analyze the canister samples using gas chromatography/mass spectroscopy (GC/MS). IDEM follows EPA Method TO-15 and established quality assurance procedures to ensure the GC/MS system is calibrated to measure concentrations of target volatile organic compounds.

The samples are analyzed for 62 target compounds using the same method used to analyze the standards, and concentrations of toxic compounds are reported. Once the sample analysis is complete, IDEM enters the data into its Office of Air Quality Toxics Data Collection (OAQTDC) database and submits quality assured data to U.S. EPA’s Air Quality System (AQS), which is a database of ambient air monitoring data from around the nation. IDEM’s Air Toxics Data map provides links to data for each monitoring site. The Air Toxics Program provides a description of current air toxics monitoring sites.

Tour of IDEM's Air Toxics Laboratory

Following is a virtual tour of IDEM’s in-house laboratory, which enables chemists to perform analysis of a wide array of air toxics. Over the years, the instrumentation used for the sampling and analysis of air toxics has become increasingly sophisticated, enabling increased accuracy in the measurement of levels of pollutants in the air. IDEM continually strives to optimize its instrumentation and methodology to provide the most accurate data possible.

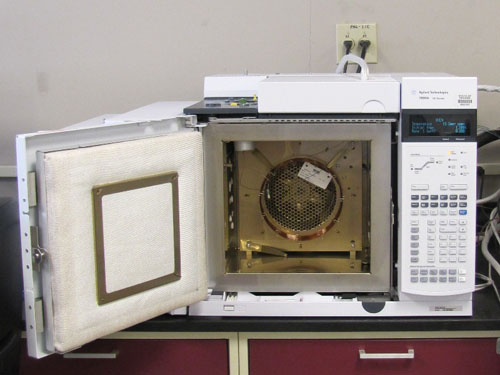

The view as you enter IDEM's Air Toxics Laboratory.

A workstation used by IDEM's laboratory chemists to analyze air toxics samples. The instrument on the left is a GC/MS (gas chromatograph/mass spectrometer) system.

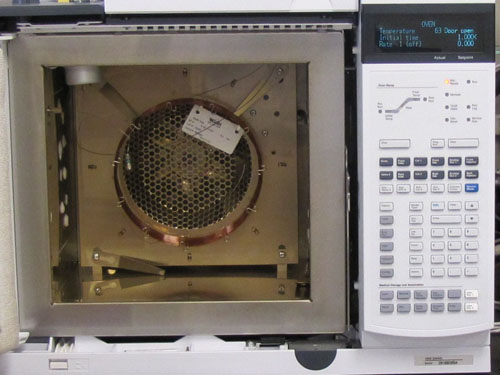

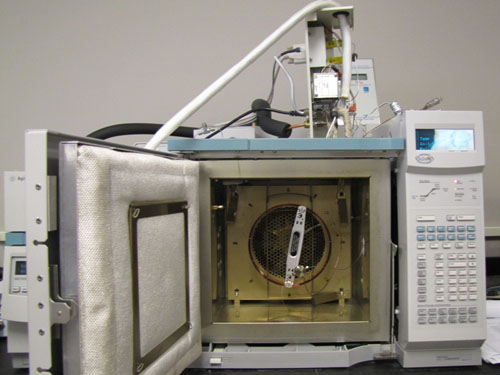

A close up of IDEM's newest GC/MS.

The inside of the GC/MS is heavily insulated because the GC/MS can heat up to several hundred degrees while conducting a sample analysis. The ring in the middle is called a capillary column. It is made from a special kind of glass called fused silica. It is a very long tube (almost 200 feet long) with very small diameter (0.32 mm, about the size of a single grain of salt). The sample is fed through the column to help separate the individual pollutants within the sample so they can be analyzed. The individual pollutant is identified by their retention time (the time it takes for them to travel all the way through the column), which is based on their molecular weight, boiling point, and polarity.

A closer shot of the inside of the GC/MS system shown in the previous picture.

The instrument in the center is a GC/FID (gas chromatograph/flame ionization detector) system. It measures the TNMOC (total non-methane organic compounds) of the sample. This gives the chemists an idea of how much total pollutant there is in the sample. This is important to know because if there is too much total pollutant in a sample it can damage the GC/MS system. If the GC/FID detects a high concentration of pollutants in the sample the chemists can dilute the sample (add extra clean air) so it doesn't damage the GC/MS. After the sample is analyzed they then multiply the results by the dilution factor (based on the amount of air added) to determine the actual concentration in the original sample.

This is an auto sampler interfaced with the GC/MS system for VOC analysis. The auto sampler has capacity to connect sixteen canister samples in a batch. Each sample analysis takes over an hour to run. The auto sampler is programmed to automatically feed the next sample to the GC/MS system to be analyzed.

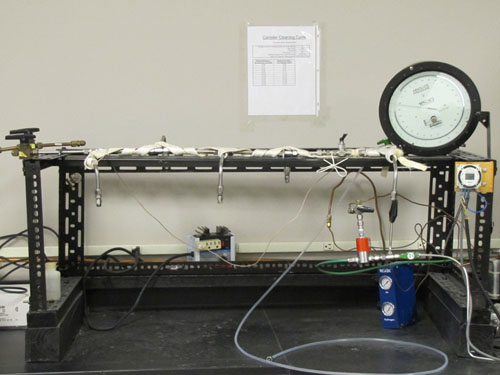

This is an absolute pressure gauge. It is used to measure canister pressure very accurately. The system is part of the canister clean up assembly and measures the canister pressure after sampling to establish the consistency of the monitoring program.

This is a canister clean up assembly. The oven is used to heat the canisters to 90oC during the cleaning cycle. After they are cleaned, the batch is certified clean and all canisters are evacuated to be used for the next sampling event.

A rack of clean, evacuated Summa canisters ready to be used for the next sampling date.

Additional shot of the auto samplers and a liquid nitrogen tank. Liquid nitrogen is used as a cryogen (refrigerant) for the auto samplers.

Inside IDEM's other GC/MS system. This system is used for duplicate analysis as part of the quality control process. It also acts as a backup system for the main GC/MS system.